Porcelain production

Mastering various technological processes makes us a leader in the field

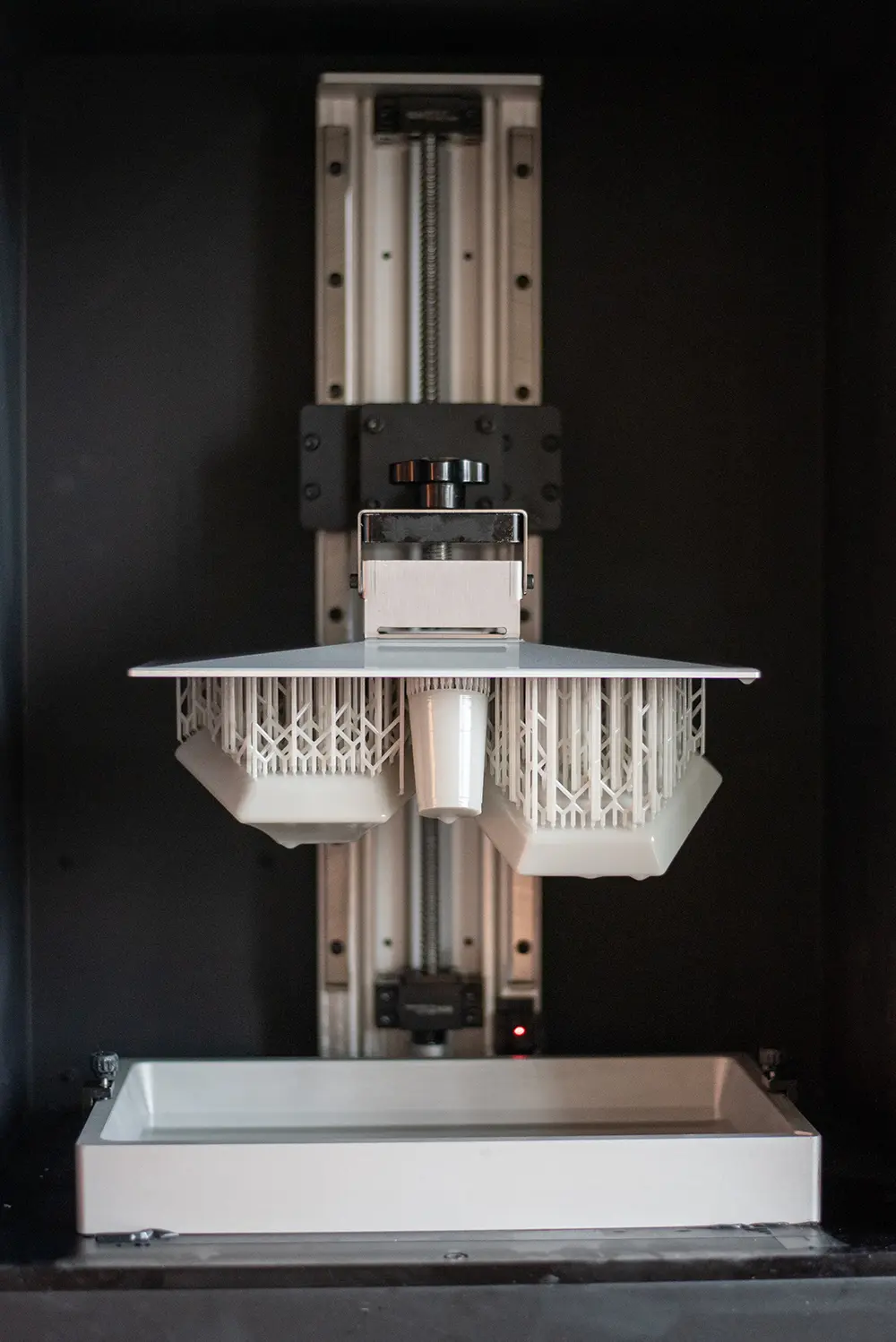

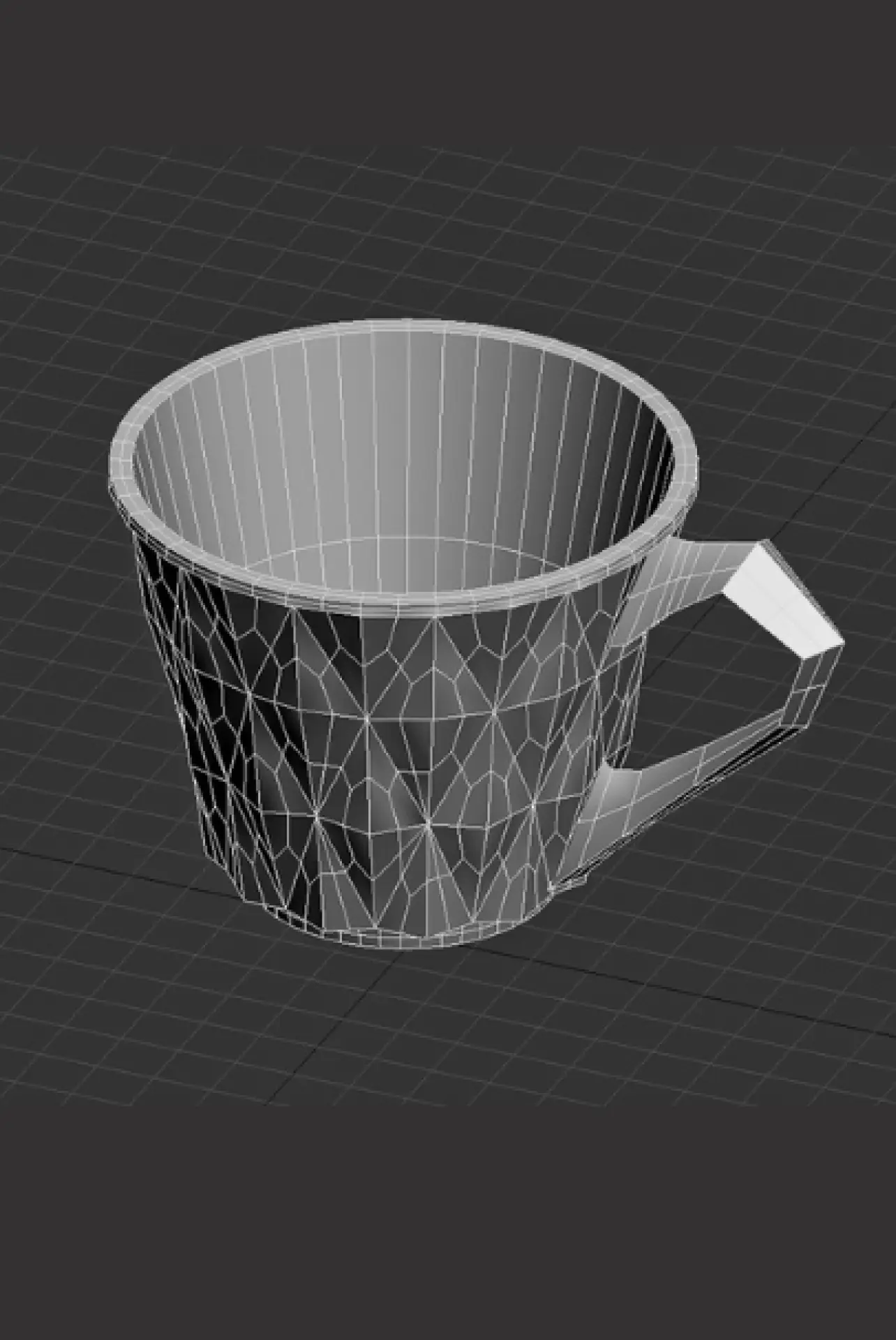

3D model design and production

At the beginning is the product design.

This is followed by the production of a model, which is increased by 14% due to shrinkage during firing. A plaster mold (so-called main mold) is made for this model.

Production of molds

If the first castings from the main mold are in order, we continue to produce operating molds.

Pouring into plaster molds

Liquid porcelain mass is poured into a plaster mold.

Plaster aspirates portion of water from the mass and thereby creating a wall of the product - so called 'shard'. The wall thickness of the product is directly proportional to the time during which the material is in the mold. The mass is poured out when the desired thickness of the shard. Gypsum (calcium sulfate) gives the product limestone, which contributes to the fact that the product soon after casting solidifies to a state in which it can be pulled out from the mold. For rotary products we use turning technology.

Drying and retouching

Once the product is made it is left to dry and then joints and imperfections are retouched.

Biscuit firing and glaze firing

Then it is burned at a temperature of 950°C - Biscuit firing.

Fired goods is glazed and goes back into the furnace. Our products are burned at a temperature of 1380°C, usually in a reducing environment.

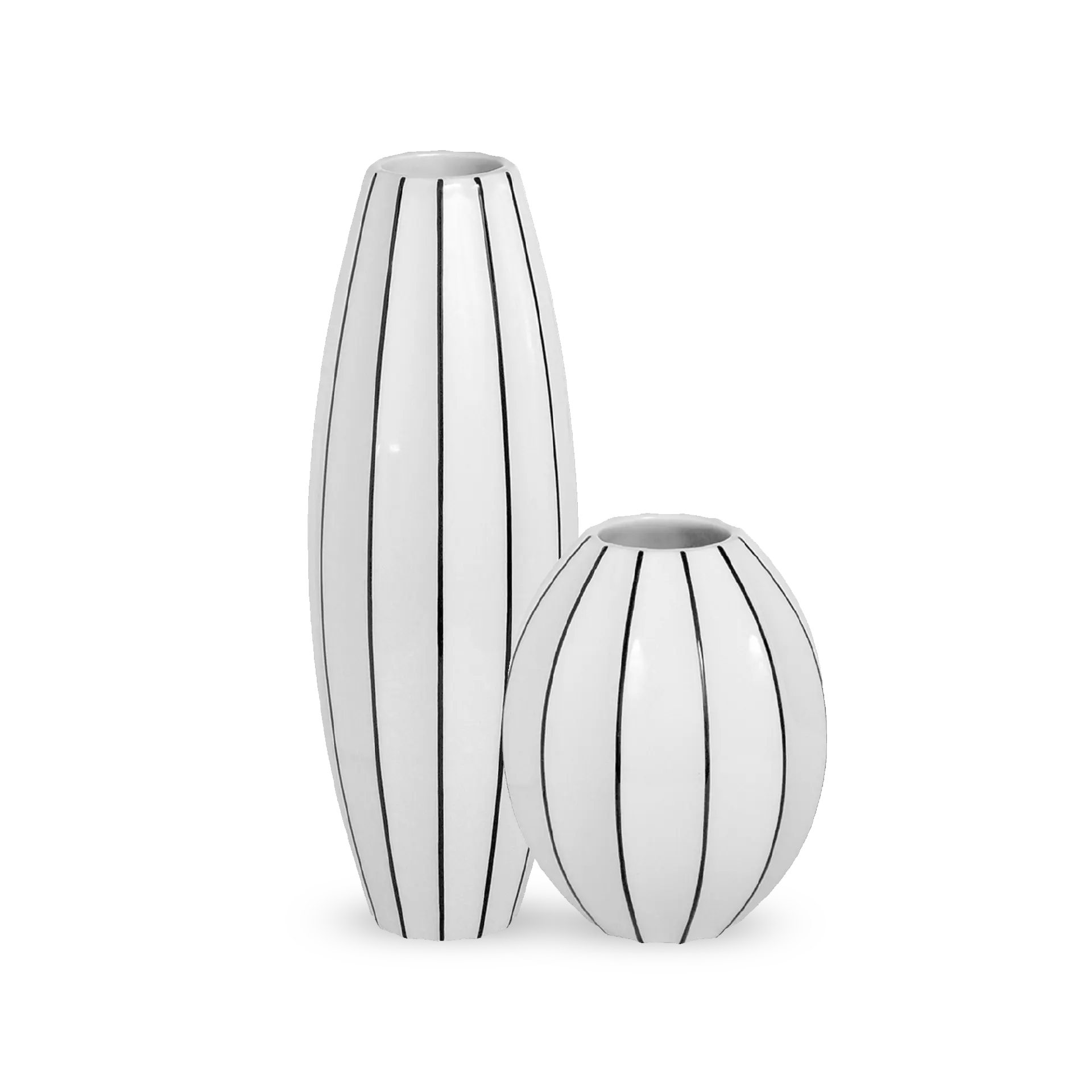

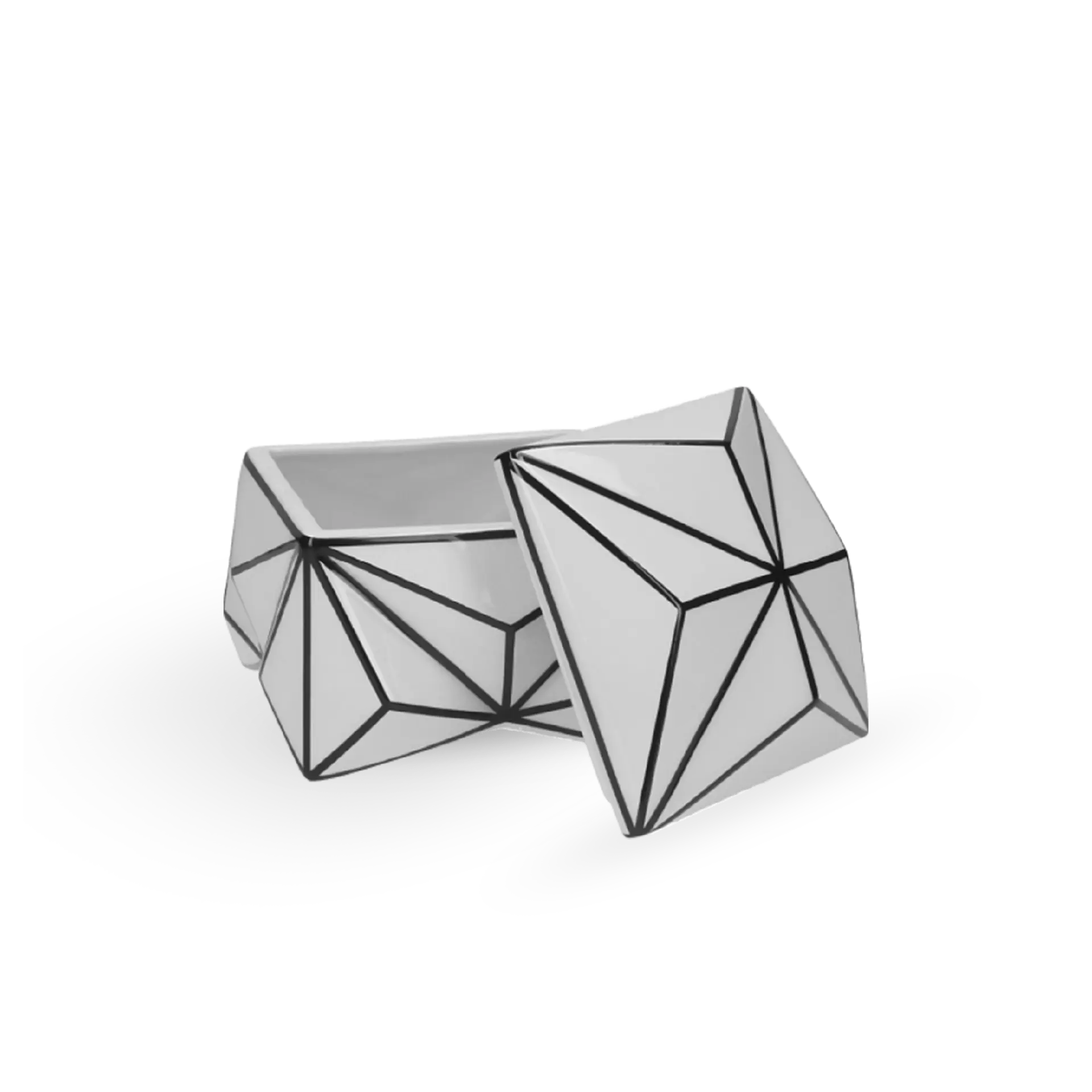

Decorating

Then the white product is decorated

Then the white product is decorated. We use glazing decoration paints or paints containing precious metals such as gold or platinum. Also, we use decoration salts (metal chlorides). Decoration is done by traditional methods and, for example, metal salts decoration under glaze is a classic porcelain technique that is used by few manufacturers. Thereafter, the decorated product is again fired, this time at 800°C.

Shipping

After the cooling down, we check the product carefully and pack in special protective boxes. And after that goes directly to you.